In the world of ergonomics, Inertial Measurement Units (IMUs) play a crucial role in capturing precise motion data. But how many sensors do you actually need for different assessments? When you’re analyzing workplace ergonomics having the right number of IMUs ensures accurate and reliable data collection.

Let’s break down the minimum IMU requirements for key analyses:

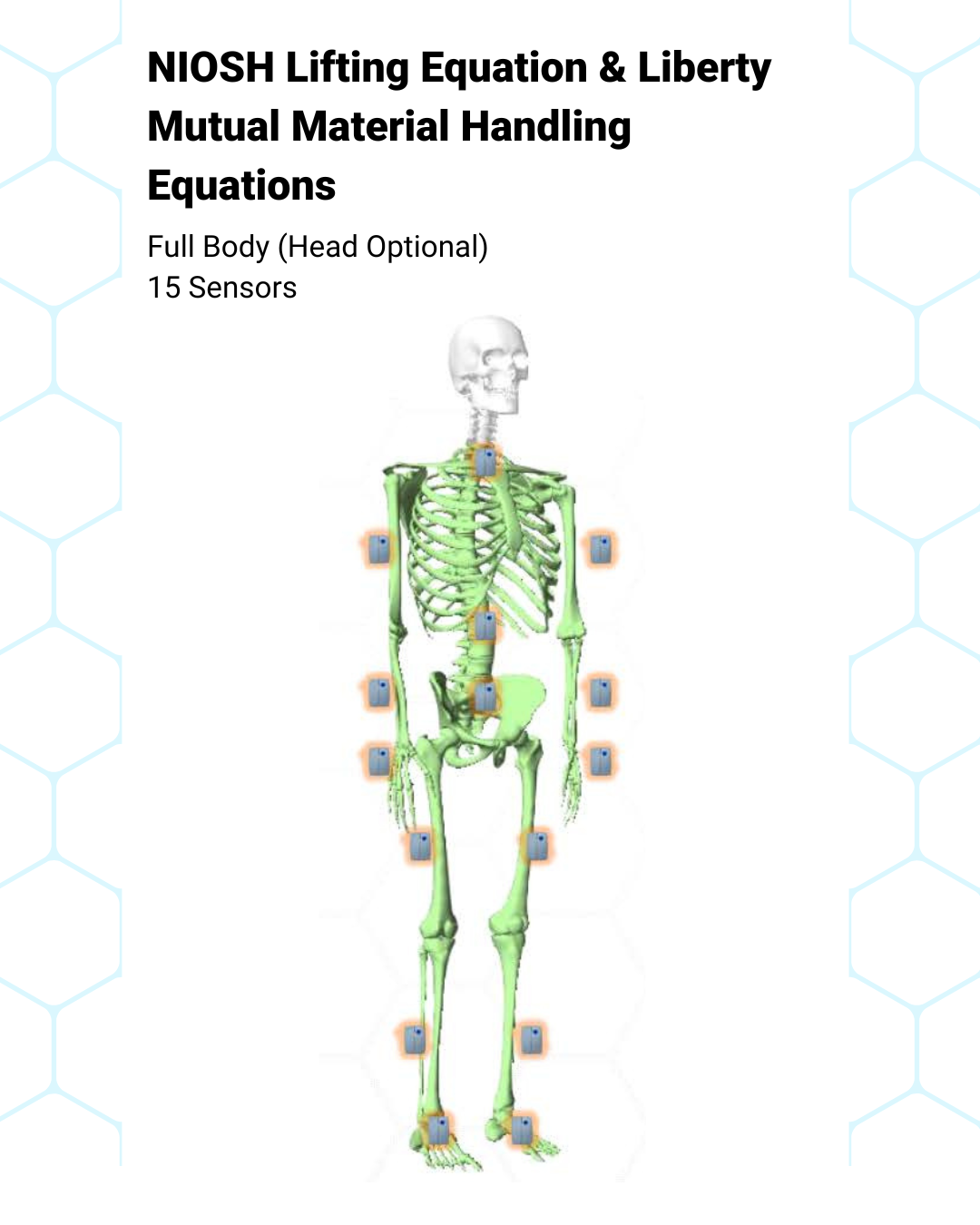

NIOSH Lifting Equation & Liberty Mutual Material Handling Equations

Minimum IMUs: 15+

For lifting and carrying tasks, the NIOSH Lifting Equation and Liberty Mutual Manual Material Handling Guidelines help assess safe load limits and risk exposure. These assessments require 15 IMUs for full-body tracking, with an optional sensor for the head.

Best for:

- Determining safe weight limits for lifting and carrying

- Preventing back injuries in logistics, warehousing, and manufacturing

- Optimizing material handling techniques to reduce fatigue

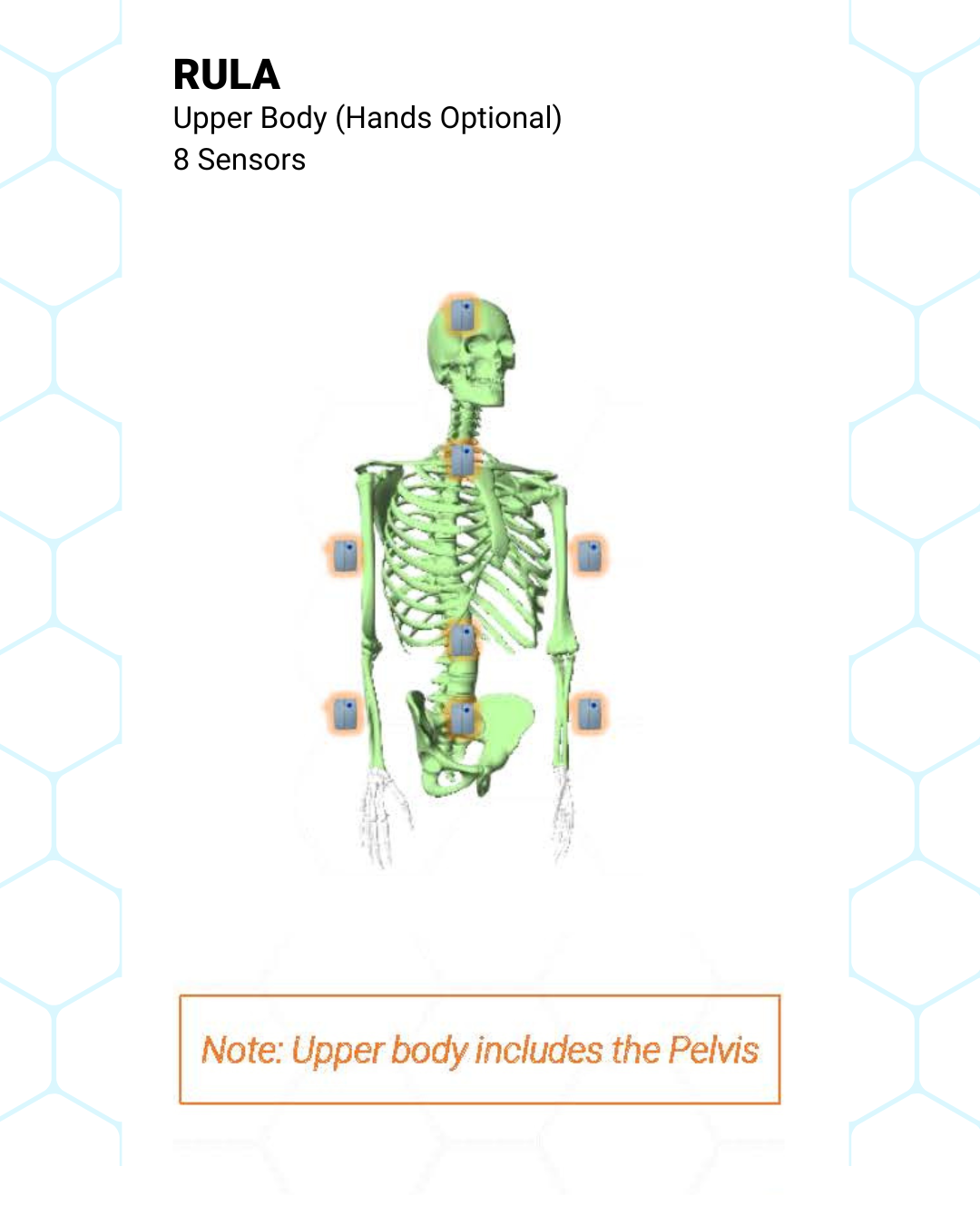

Rapid Upper Limb Assessment (RULA)

Minimum IMUs: 8+

RULA is designed to analyze upper-body movements, particularly in repetitive tasks or static postures. This assessment requires eight IMUs, with optional sensors for the hands, to track arm, wrist, and shoulder positioning.

Best for:

- Assessing ergonomic risks in office work, manufacturing, and assembly line tasks

- Preventing repetitive strain injuries (RSIs)

- Optimizing workstation design and tool use

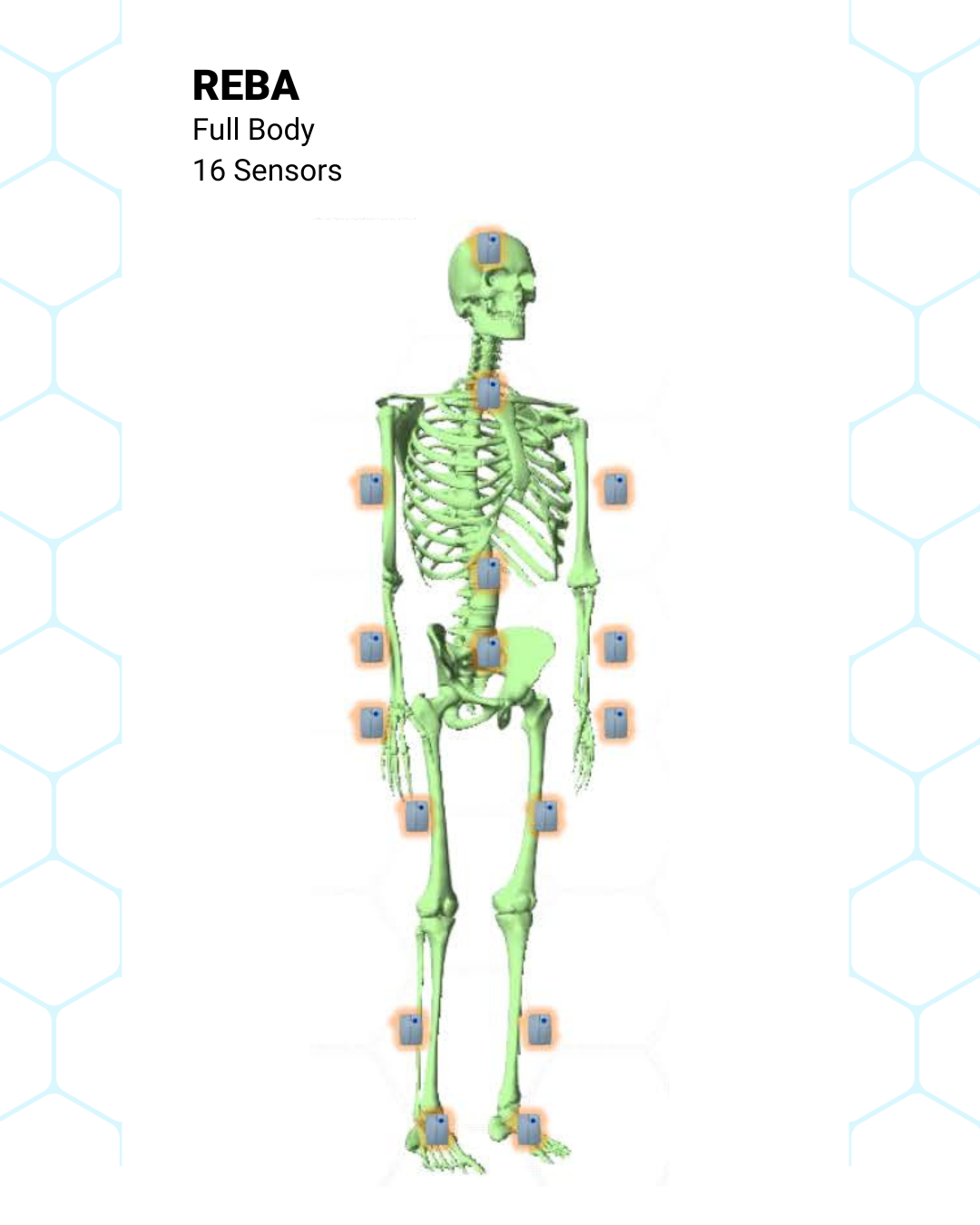

Rapid Entire Body Assessment (REBA)

Minimum IMUs: 16

REBA evaluates whole-body posture and identifies ergonomic risk factors in various workplace tasks. To conduct a full-body REBA assessment, 16 IMUs are required, ensuring accurate data capture from head to toe.

Best for:

- Evaluating posture risk in physically demanding jobs

- Assessing awkward or unstable work positions

- Identifying potential musculoskeletal strain

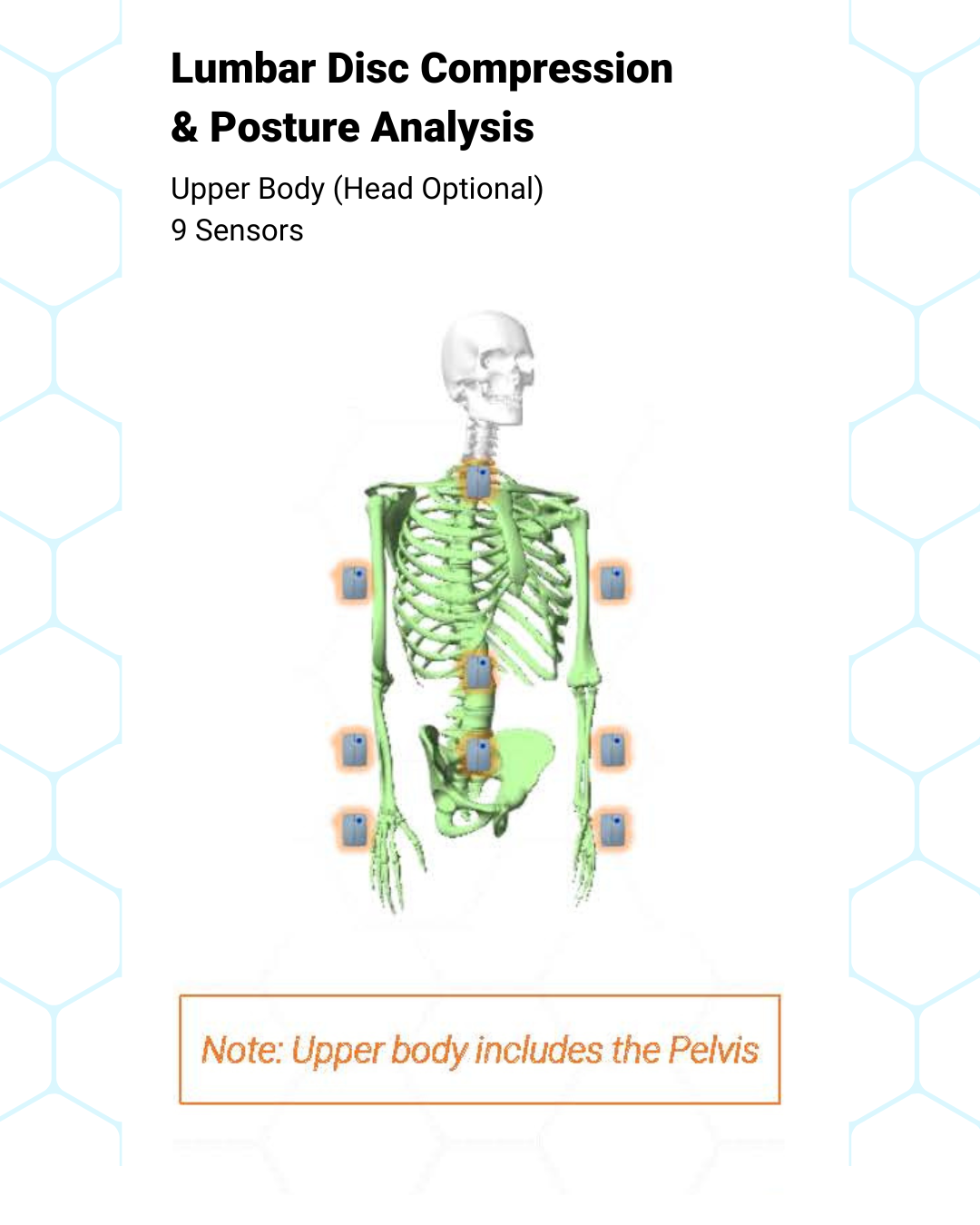

Lumbar Disc Compression & Posture Analysis

Minimum IMUs: 9+

The Lumbar Disc Compression analysis calculates lumbar disc compression forces using user-selectable equations from McGill, Merryweather, and Potvin. Compression values are classified based on the NIOSH Action Limit of 3400 N, categorizing results into “Above Limit” and “Below Limit” zones. For enhanced tracking, an optional head sensor can be integrated.

Posture analysis helps identify potential ergonomic risks by categorizing postures into three risk zones: green (low risk), yellow (moderate risk), and red (high risk).

Together, these tools provide a comprehensive assessment of upper-body movement, spinal loading, and lumbar strain during both static and dynamic tasks, helping users optimize workplace safety and ergonomics.

Best for:

- Evaluating spinal loading, lumbar stress, and posture risks

- Preventing lower back injuries and musculoskeletal disorders in physically demanding tasks

- Designing ergonomic interventions for lifting tasks and prolonged postures to improve comfort and safety

Why IMUs are Essential for Ergonomic Evaluations

Traditional ergonomic assessments rely on observational methods, which can introduce subjectivity and variability. IMUs offer a data-driven approach, providing quantifiable insights into movement patterns, posture, and strain. By using the recommended minimum number of IMUs, professionals can:

- Improve assessment accuracy

- Identify risk factors early

- Develop effective ergonomic interventions

- Enhance worker safety and performance

Whether assessing lifting mechanics, workstation ergonomics, or full-body movement efficiency, utilizing the appropriate number of IMUs ensures precise, reliable, and data-driven insights. For organizations committed to injury prevention and workplace optimization, IMU-based assessments provide a transformative approach to ergonomic evaluation.

Ready to elevate workplace safety through advanced biomechanical analysis? Reach out to learn how the right IMU configuration can enhance the accuracy and effectiveness of your ergonomic assessments.